More than £1.4 million has been invested at Hanson’s Whatley quarry near Frome in Somerset to produce high quality aggregates for construction of the UK’s new nuclear power station at Hinkley Point in Somerset.

Waste minimisation

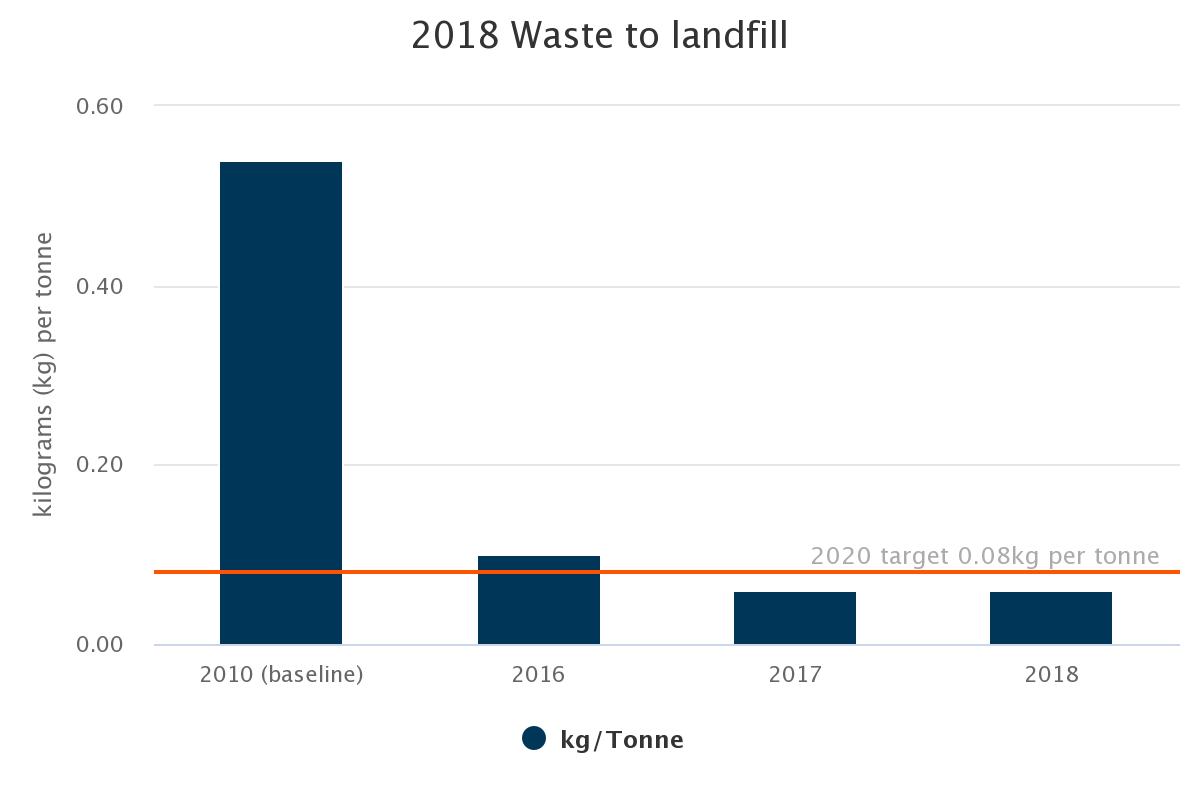

We passed our 2020 target of an 85 per cent reduction in waste to landfill per tonne of product based on the 2010 baseline figure. The target has been achieved through a company-wide commitment to operate efficiently and recycle or reuse as much waste as possible. The amount of waste sent to landfill in 2017 fell by 35 per cent on the prior year.

The majority of our sites are included within a single contract with Biffa a national waste management company which enables us to control the process more effectively and maintain data on the quantity and types of waste being produced.Another way in which we are reducing waste is by processing by-products from the production of aggregates which might otherwise be returned to the quarry void. Many of our quarries produce far more fine material and dust than they can sell so we are investing in washing and processing plants to create a manufactured sand for use in our concrete plants as a substitute for land-won and marine sand. At Whatley quarry in Somerset we have installed a processing plant to produce manufactured sand which can then be transported by rail to London and south-east England where supplies of land-won sand are becoming increasingly scarce.

-

Waste to landfill

2010 (baseline)

2015

2016

2017

Total tonnes

18,472

8,095

3,996

2,563

Kg/tonne product

0.54

0.20

0.10

0.06

When normalised for production changes at business line level, the 2017 performance is 0.07kg. waste /tonne against a 2010 baseline of 0.50kg waste /tonne, showing a reduction of 86.2%.

-

Cement specific waste – by-pass dust – tonnes

2010 (baseline)

2015

2016

2017

Produced

5,619

10,336

9,823

8,277

Landfilled

2,979

0

0

0

Diverted from landfill

47%

100%

100%

100%